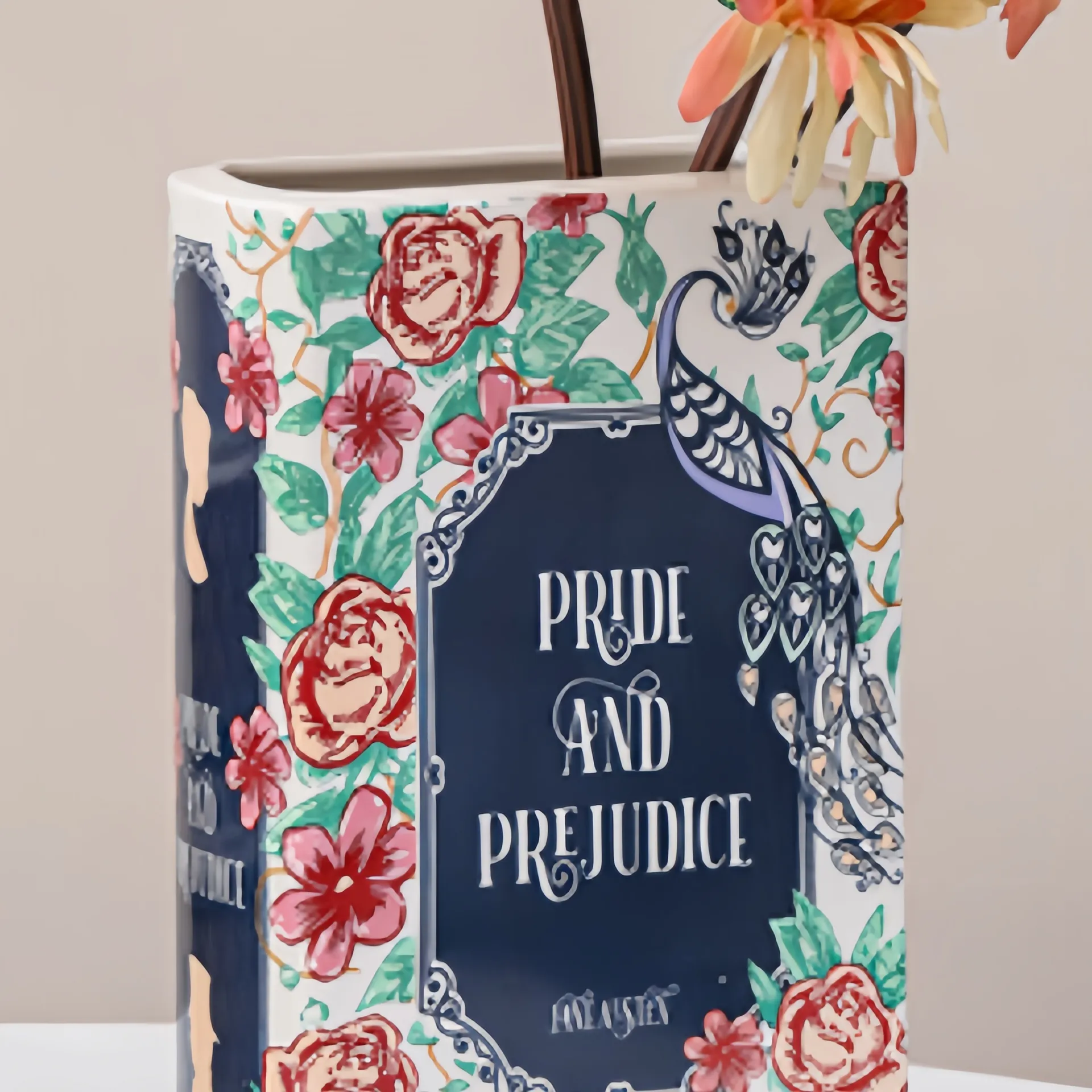

Din enda leverantör av keramiska vaser

Vad vi levererar

Utforska vårt breda utbud av mönster

Den service vi kan erbjuda

OEM-lösning

Lösning för partihandel

Mästerlig kundanpassning - skräddarsy varje detalj efter din vision

Dekorationshantverk - Konstnärskap i varje mugg

Stabil produktionskapacitet

Vår tillverkningsanläggning är utrustad med automatiserade maskiner och tunnelugnar för att öka effektiviteten och skala upp produktionen.

Det gör att vi kan leverera stora volymer och samtidigt hålla en jämn kvalitet och konkurrenskraftiga priser.

Oavsett om du behöver några hundra delar eller tiotusentals, ser vi till att leverera i tid utan att kompromissa med hantverksskickligheten.

- Fabriks produktionsområde över 42.000㎡

- 3 tunnelugnar, 4 kubikugnar och 2 automatiserade

- Årlig produktion på 5 miljoner USD

- Över 300 erfarna medarbetare

Från lera till keramik: Vår produktionsprocess

Gjutning

Vi använder tre gjutningstekniker för att forma rå lera: hålgjutning, högtrycksgjutning och rullformning.

Trimning

Fogar, grader och partiklar trimmas noggrant för att säkerställa en slät och jämn yta.

Tvättning

Varje föremål torkas noggrant av med en fuktig svamp för att avlägsna damm och orenheter.

Bisquebränning

Den första bränningsprocessen för att härda leran före glasering.

Dekoration

Applicering av konstnärliga element som handmålning eller dekaler.

Glasning

Glasyren appliceras jämnt för att ge färg, glans och ökad hållbarhet.

Bränning av glasyr

Det sista steget i ugnen för att befästa produktens hållbarhet och utseende.

Dropptestförpackningar för säker leverans

Vad som skiljer oss åt

Stormarknader

Återförsäljare

Vi erbjuder lösningar för

Grossister

E-handlare

Ta en titt på våra globala partners