Your One-Stop Ceramic Vase Supplier

What we supply

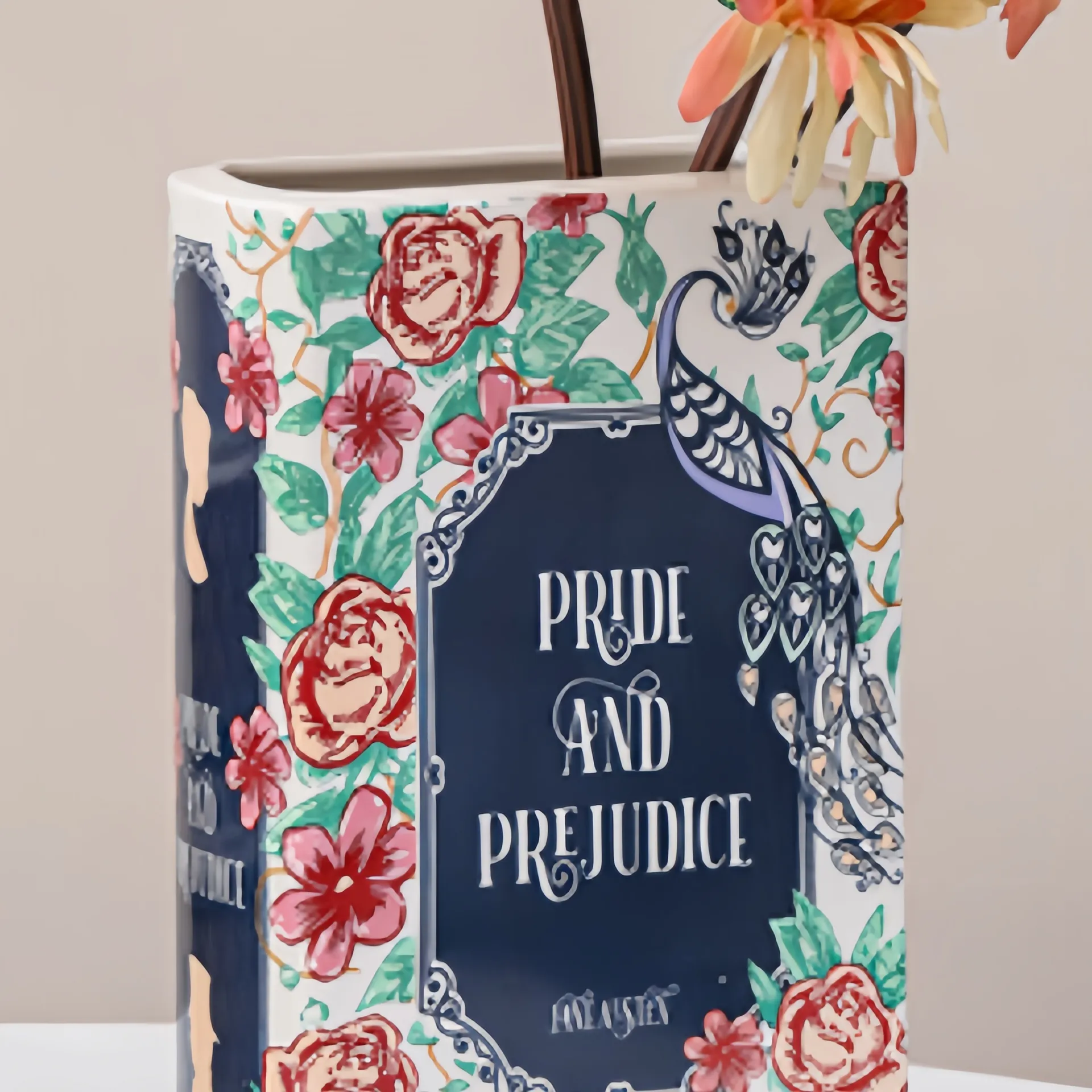

Explore Our Wide Range of Designs

The Service We Can Provide

OEM Solution

Wholesale Solution

Masterful Customization - Tailor Every Detail to Your Vision

Decoration Craft - Artistry in Every Mug

Stable Production Capacity

Our manufacturing facility is equipped with automated machinery and tunnel kilns to enhance efficiency and scale production.

This allows us to meet large-volume orders while maintaining consistent quality and competitive pricing.

Whether you need a few hundred pieces or tens of thousands, we ensure timely delivery without compromising craftsmanship.

- Factory production area over 42,000㎡

- 3 tunnel kilns, 4 cubic kilns, and 2 automated

- USD 5 million annual output

- Over 300 experienced workers

From Clay to Ceramic: Our Production Process

Molding

We employ three molding techniques to shape raw clay: hollow casting, high-pressure casting, and rolling forming.

Trimming

Seams, burrs, and particles are carefully trimmed to ensure a smooth, even surface.

Washing

Each piece is carefully wiped with a damp sponge to remove dust and impurities.

Bisque Firing

The first firing process to harden the clay before glazing.

Decoration

Application of artistic elements such as hand-painting or decals.

Glazing

Glaze is applied evenly to provide color, shine, and increased durability.

Glaze Firing

The last step in the kiln to solidify the product’s durability and appearance.

Drop Test Packaging for Safe Delivery

What Sets Us Apart

Supermarkets

Retailers

We Offer Solutions For

Wholesalers

E-retailers

Take a Look at Our Worldwide Partners